Don't hesitate to send a message

I. Introduction: Solving the "Impossible" Task The phrase "fitting a square peg into a round hole" is a universal symbol...

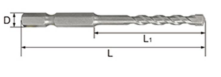

READ MOREWhether the drill pipe can meet the requirements of the project, not only to control the production process of the drill pipe, but also the transportation loading and unloading of the drill pipe.

1. Before the drill pipe is unloaded, make sure that the protective wire is not tightened.

2. Do not fall when unloading the drill pipe, and do not let the end of the drill rod collide, because even if there is a guard, the wire buckle may be damaged.

3. Removed drill pipes must be put together neatly.

4. Drill rod connector withstand huge torque in work, threads wear and stick, so it is necessary to apply a wire buckle.

5. Avoid forbidden to force the bonded threads. At the time of deduction, the male tooth may be located on the corresponding female buckle tooth, causing a tight effect. Forcibly, it will cause serious damage.

6. When the drill rod is placed under the lifting card, do not cause the lifting card or the hook to the mother joint shoulder.

7. The drill rod is used, and the outer surface and inside of the drill pipe must be washed with water, and it is necessary to apply anti-rust oil on the joint thread and shoulders; the drill pipe pulls out the door, we must wear a protective wire.

8. Damaged drill pipes are not allowed to come into the well. If the damaged public connections are received on the unscrupulous parent connector, they will make the female joints and vice versa.

I. Introduction: Solving the "Impossible" Task The phrase "fitting a square peg into a round hole" is a universal symbol...

READ MOREMetalworking has always been a cornerstone of industrial development, shaping everything from automotive components to a...

READ MORE1. What Are Waterpump Pliers? – The Flexible “All-Rounder” Tool In modern industrial manufacturing and daily maintenance...

READ MORESelecting the appropriate industrial cutting tools is a critical decision that directly impacts manufacturing efficiency...

READ MORE+86-573-84611229

+86-573-84611518

NO.35 Yucao Road, Ganyao Town, Jiashan City, Zhejiang Province, China