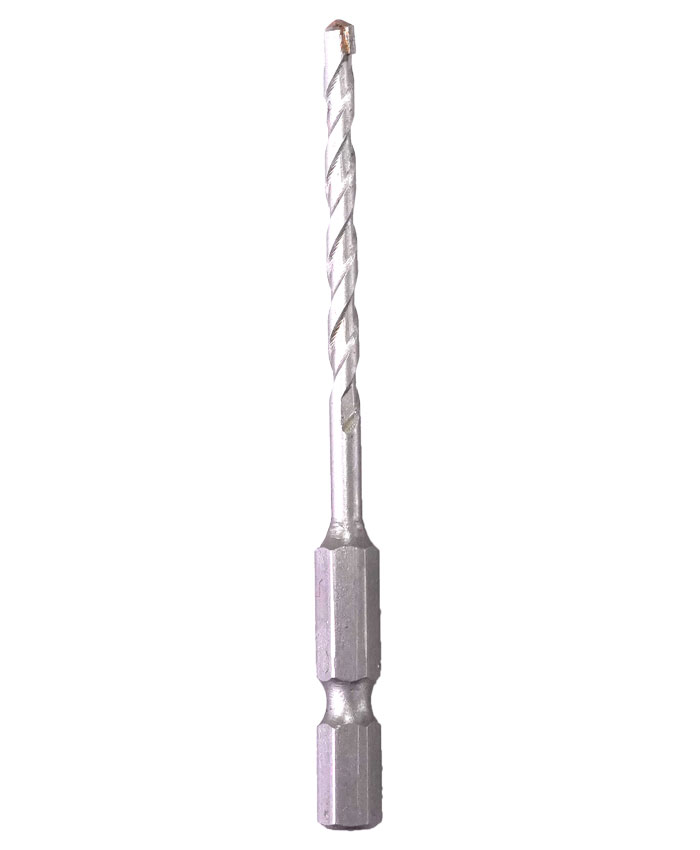

Preparation of diamond bit before drilling 1. Check the […]

Preparation of diamond bit before drilling

1. Check the previous diamond bit for damage to the bit body, tooth loss, etc., and make sure the bottom of the well is clean and free of falling objects.

2. Carry the diamond bit carefully and place the diamond bit on a rubber pad or wooden board. It is forbidden to place the diamond bit directly on the iron plate.

3. Check whether the cutting teeth of the diamond bit are damaged, whether there is any foreign matter in the diamond bit, whether there is an O-ring in the nozzle hole, and install the nozzle as needed.

Diamond drill bit up buckle

1. Clean the male button or female button of the diamond bit and apply thread oil.

2. Clamp the shackle on the diamond drill bit, and lower the drill string to make it contact with the male or female buckle to buckle.

3. Put the diamond drill bit and the shackle into the turntable to fill the core, and then tighten the thread according to the recommended tightening torque value.

Drill down

1. Lower the diamond bit slowly, especially slowly through the turntable, blowout preventer, and casing hanger to protect the cutting teeth.

2. Pay attention to the well block encountered during the last trip. When you encounter reduced diameter and dog legs during the drilling process, the drill bit should pass through slowly.

3. When a single root is about 1 to the bottom of the well, it starts to rotate at a drilling speed of 50~60rpm and the pump is started to flush the bottom of the well with a rated displacement.

4. Pay attention to the indicator weight and torque to make the diamond bit touch the bottom of the well smoothly.

Diamond drill bit cuts the eye

1. It is not recommended to use diamond drill bits for borehole demarcation.

2. If eye-drawing is necessary, the eye-drawing should be carried out slowly and with a low torque at the rated displacement.

Diamond drill bit shape

1. Keep the rated displacement and lower the diamond bit to the bottom of the well.

2. Use slow drilling at least 1m to establish a bottom hole model.

3. Increase the drilling pressure to the best value for normal drilling with an increase of 10kN each time. Excessive pressure is strictly prohibited, which may cause early damage to the diamond bit.

4. Keep the WOB constant and adjust the drilling speed to obtain the best combination of drilling parameters.

Diamond drill bit drills normally

1. When encountering strong abrasive or hard sandy mudstone, reduce the drilling speed to extend the life of the diamond bit.

2. Adjust the drilling speed and diamond bit when encountering formation changes or interlayer to maintain the best drilling performance.

3. Pay attention to the following points each time you receive a single root:

3.1 Restore the pump strokes and check the standpipe pressure.

3.2 Start the pump before the diamond bit touches the bottom of the well, and slowly lower the diamond bit to the bottom of the well at a drilling speed of 50-60 rpm.

3.3 Slowly restore the pressure to the original diamond bit, and then increase the drilling speed to the original drilling speed.

Field use proves that when drilling in soft-medium-hard formations, the diamond bit has the advantages of high speed, large footage, long life, stable work, fewer downhole accidents, and good well quality. Diamond drill bits are not only used for a long time, but also can be reused. The use effect of the returned diamond drill bit is similar to that of the factory diamond drill bit, which can save a lot of drilling costs.